FujiFilm Anti-Fog Film

Couldn't load pickup availability

Fujifilm's anti-fog film utilizes a unique base film material commonly used in applications requiring excellent optical properties, such as photographic films and display materials. Furthermore, this base film is subjected to a special surface treatment to achieve superior properties.

1) Stable anti-fog performance due to hygroscopicity. In addition to the hygroscopicity of the base film itself, the surface treatment further increases its hygroscopicity. Therefore, attached vapor is quickly absorbed by the surface. It does not form water droplets and has stable anti-fog performance.

2) High transparency is achieved through the material properties of the transparent base film and the film manufacturing technology.

3) Durability: With conventional coatings, the coating material can be removed by wiping and cleaning, compromising anti-fog performance. In contrast, Fujifilm uses a special surface treatment method, rather than a coating. The anti-fog functional layer is integrated with the base film, achieving high durability.

4) Use natural biomass raw materials with a biomass content of more than 40%.

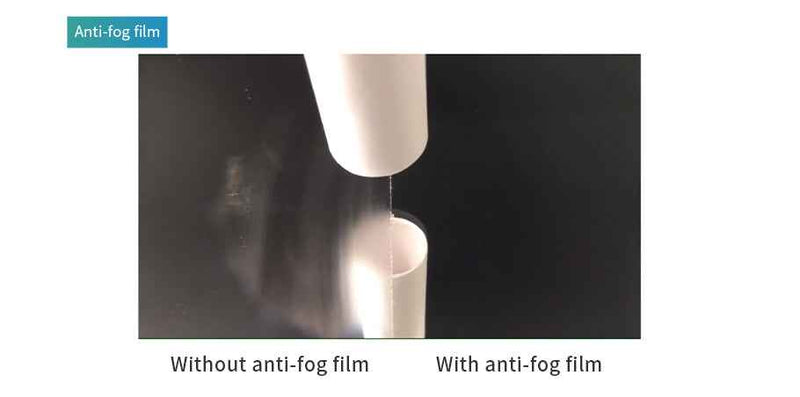

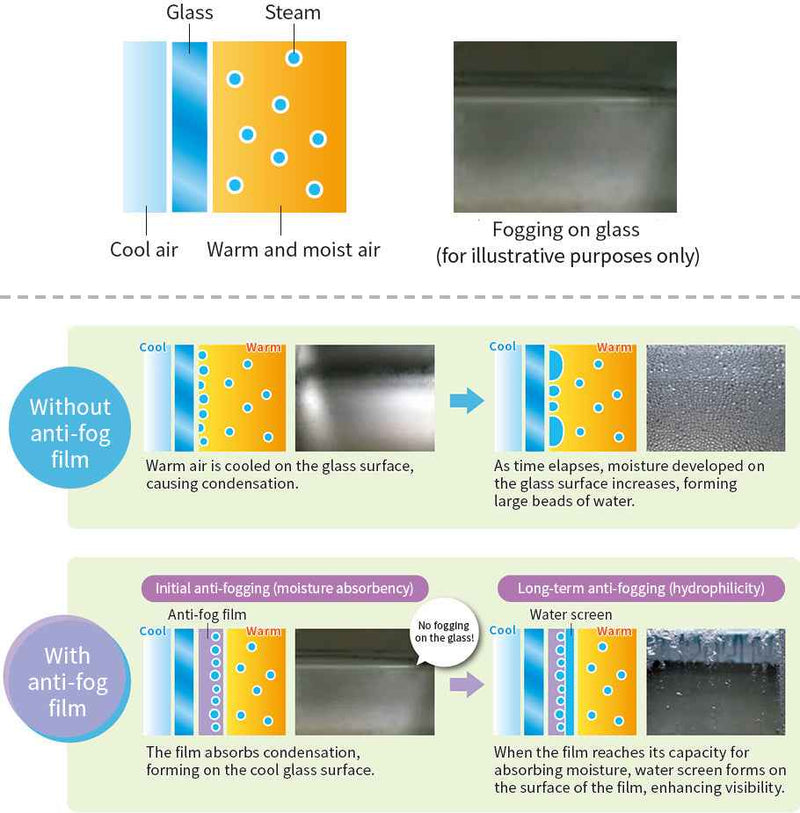

Anti-fog mechanism <br>For glass without anti-fog film, when warm air cools on the glass, condensation will begin. The amount of moisture attached to the glass surface increases over time, and the water droplets become larger and larger, causing condensation on the glass. It appears "turbid."

For glass coated with Fujifilm's anti-fog film, condensed water is initially absorbed by the film (hygroscopicity). Furthermore, when the film reaches saturation, a water film forms on the film's surface. The water vapor that ultimately adheres quickly becomes compatible with the surface (hydrophilicity) and does not form droplets, thus reducing fogging. This allows for a relatively long period of visibility, from the time water vapor begins to adhere until saturation and the formation of a water film.